MIL-DTL-28619D

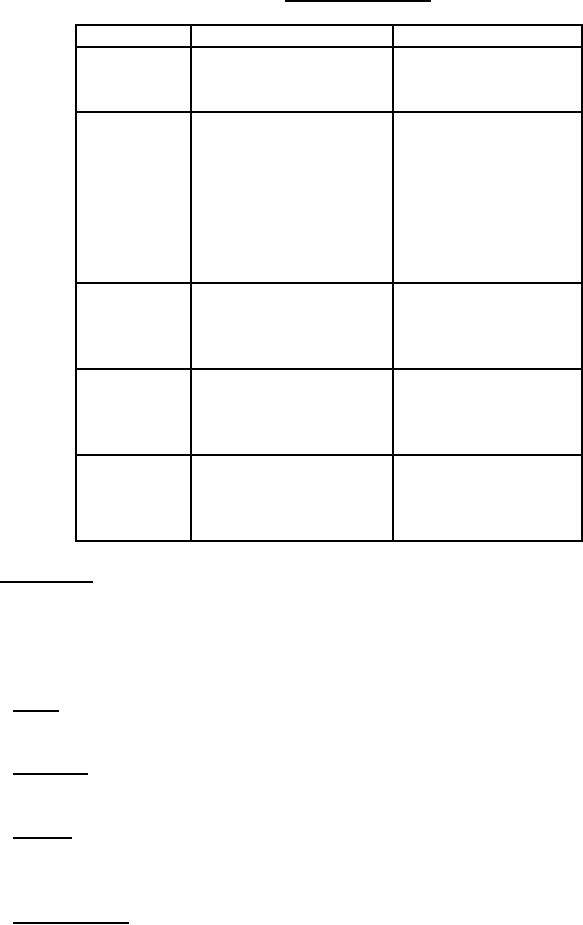

TABLE I. Applicable drawings.

Class

Nominal weight, lb (kg)

Applicable drawing no.

1

200 (91)

813507

813508

813509

2

3,000 (1 361)

813510

813511

813512

813584

3

6,000 (2 722)

813513

813514

813515

813583

4

9,000 (4 083)

813516

813517

813518

813561

5

12,000 (5 443)

813519

813520

813521

879085

6

15,000 (6 804)

813503

813504

813505

813464

3.4 Construction. The complete anchor assembly shall conform to the requirements and

dimensions specified herein and on the applicable drawings. No deviation from the prescribed

dimensions or tolerances is permissible without prior approval of the contracting officer. The

tolerance criteria of the fluke angle with respect to the anchor shank shall be 50 degrees

± 1 degree for mud use, and 34 degrees ± 1 degree for sand use.

3.4.1 Shank. The shank shall be either cut from structural steel conforming to ASTM A 36, or

forged from steel conforming to ASTM A 668, class D.

3.4.2 Stabilizers. Stabilizers for class 1 anchors shall be welded to the to the anchor. Stabilizers

for class 2 through class 6 should be hinged or welded as specified (see 6.2).

3.4.3 Wedges. Unless otherwise specified (see 6.2), wedges will be provided. When provided,

the required number and sizes of bolts, nuts, and washers shall also be provided for complete

installation. Bolts, nuts and washers should conform to ASTM A 325.

3.4.4 Palm extensions. Unless otherwise specified (see 6.2), palm extensions shall be provided

for field welding to the tripping palms. When palm extensions are to be shop welded to the

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business