MIL-DTL-28619D

tripping palms, an alternate fabrication method may be used. The alternate method permits the

palm extension and the tripping palm to be fabricated from one continuous piece of structural

steel.

3.4.5 Shackle and pin. A shackle and pin conforming to ASTM A 668, class K, shall be

provided.

3.5 Performance.

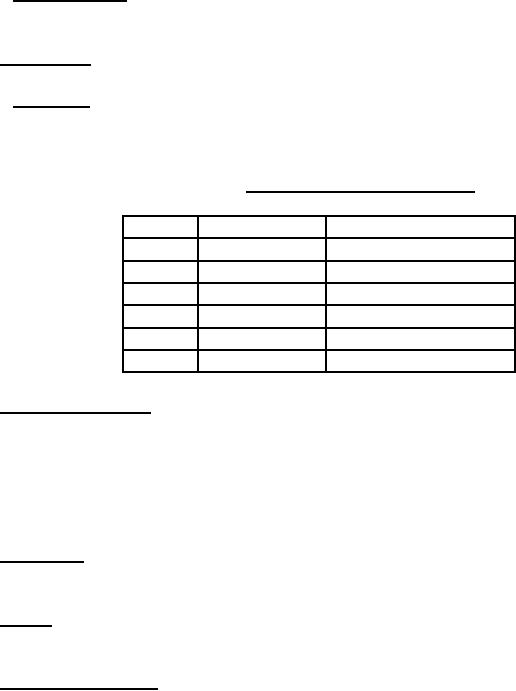

3.5.1 Proof load. The complete anchor assembly shall be capable of withstanding a proof load

for the applicable class of anchor as shown in table II without damage, permanent deformation,

cracks, or distortion. The proof load shall be applied as shown on the applicable drawing.

TABLE II. Proof loads for anchors by class.

Class

Weight, lb (kg)

Proof load, lb (kg)

1

200 ( 91)

10,000 (

4 530)

2

3,000 (1 361)

72,600 ( 32 888)

3

6,000 (2 722)

121,000 ( 54 813)

4

9,000 (4 083)

156,000 ( 70 668)

5

12,000 (5 443)

185,000 ( 83 805)

6

15,000 (6 804)

214,000 ( 96 942)

3.6 Cleaning and coating. After testing and examination and before coating, all parts shall be

cleaned. All oil, grease, loose scale, and other foreign substances which would prevent bonding

of the coating to the metal should be removed. Anchor parts shall be shot blasted to near white

metal in accordance with SSPC SP-10. After cleaning, all parts shall receive one coat of asphalt

varnish conforming to A-A-1632. The asphalt coating should be not less than 3 mils

(0.08 millimetre (mm)) thick and applied in accordance with manufacturer's recommendations.

3.7 Dimensions. The dimensions and tolerances for each class of anchor and component parts

shall be in accordance with the applicable drawings.

3.8 Weight. The nominal weight of the assembled anchor shall be as specified in table II for the

applicable class of anchor.

3.9 Identification marking. Marking of each anchor shall be in accordance with MIL-STD-130.

The following information shall be stamped or raised in letters not less than 0.75-inch (19 mm)

high on both the shank and tripping palm of the anchor assembly. Stamped markings shall be

round face characters with not less than 0.06-inch (1.5 mm) depth; raised markings shall be not

less than 0.06-inch (1.5 mm) relief.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business