MIL-DTL-613D

3.2 Materials. Materials shall be as identified herein or as approved by the acquiring activity.

Acceptance or approval of any constituent material shall not be construed as a guarantee of acceptance

of the finished product.

3.2.1 Recycled, recovered, or environmentally preferable materials. Recycled, recovered, or

environmentally preferable materials should be used to the maximum extent possible provided that the

material meets or exceeds the operational and maintenance requirements, and promotes economically

advantageous life cycle costs.

3.2.2 Hazardous substances. The use of hazardous substances, toxic chemicals, or ozone depleting

chemicals shall be avoided, whenever feasible.

3.2.3 Other materials. Materials not otherwise specified shall be in accordance with applicable

specifications and to the requirements specified herein. All materials that are not specifically described

shall be of the highest quality and suitable for the purpose intended.

3.3 Construction.

3.3.1 Type I, heavy marine. Type I grapnels shall be made of steel conforming to ASTM A27/A27M

and ASTM A148/A148M grapnels shall be in accordance with table II and figures 1, 2, and 3 for sizes 1,

2, and 3, respectively. When specified the grapnel may be furnished without shackles. The eye for the

tripping line shall be of forged steel conforming to MIL-S-22698 or SAE-AMS6350 and shall be welded to

the base of the shank. Shackles shall conform to type IV, class 1 of RR-C-271.

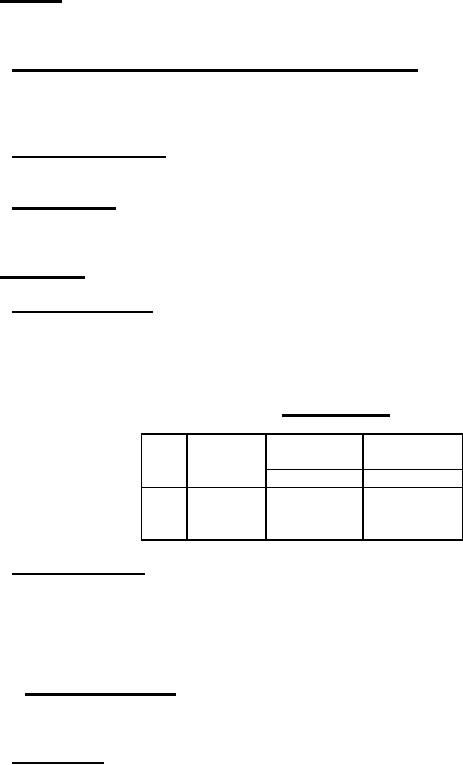

TABLE II. Type 1 grapnels.

Nominal

Size

Number

weight

of shackle

Size

of prongs

Pounds (kg)

Inches (mm)

1

4

450 (204)

1-3.8 (35)

2

5

225(102)

1 (25)

3

3

170(77)

1(25)

3.3.2 Type II, light marine. Sizes 1, 2, 3 and 4 grapnels shall have five prongs equally spaced around

the shank and size 5 grapnel shall have 3 prongs equally spaced around the shank. Class 1 grapnels

shall be made of steel as specified in MIL-S-24093 or SAE-AMS6349 or SAE-AMS6346, or

SAE-AMS6348, or SAE-AMS5349, SAE-AMS6370, or SAE-AMS6382 or SAE-AMS6528 where minimum

tensile strength is 120,000 psi. Except to use MIL-S-24093, class A, when minimum yield strength must

be 140,000 psi.

3.3.2.1 Nonmagnetic grapnels. Class 2 grapnels shall be made of nonmagnetic material conforming

in accordance with MIL-C-24707/4 or ASTM A128/A128M grade A type A (rough ground or pickled), or

type B (galvanized) or ASTM A276, type 316.

3.3.3 Sizes 1 and 2. The nominal weight of size 1 grapnels shall be 100 pounds (45kgs), and size 2

grapnels shall be 50 pounds (23kgs). The grapnels shall be constructed in accordance with figure 4. The

eye shall be fitted with a thimble capable of accommodating a rope of the circumference as specified in

table III. Thimble shall be in accordance with type I of FF-T-276. The eye for the tripping line shall be

welded to the base of the shank.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business