MIL-DTL-613D

3.3.9 Type IV, crash truck.

3.3.9.1 Size 1. Type IV, size 1 grapnels shall be made of material conforming to ASTM A108.

Grapnels shall have four prongs and be of a nominal weight of 5 pounds (2.3kgs). The dimensions and

construction details shall be as shown on figure 7. Each grapnel shall be fitted with a 60-foot (152mm),

5/16-inch diameter (.31in/7.9mm) 7 by 19 steel wire rope in accordance with RR-W-410. A 3/4-inch

(.75in/19mm) drop forged, steel, reversed eye hook shall be attached to the other end of the cable.

Thimbles shall be used in securing the cable to the grapnel and to the hook. Thimbles shall be in

accordance with type III of FF-T-276. The cable connections to the hook shall be made with an eye

splice or by the use of two 5/16 inch (.31in/7.9mm) wire rope clips. The eye splice, if used, shall be

wormed and served.

3.3.9.2 Size 2. Type IV, size 2 grapnels shall be made of steel conforming to ASTM A108. Grapnels

shall have three prongs and be of a nominal weight of 11 pounds (5kgs). The dimensions and

construction details shall be as shown on figure 8. Each grapnel shall be fitted with a 60-foot (152mm),

1/2 inch diameter ((152mm), (.5in/12.7mm), 8 by 19 plow steel, preformed, fiber core wire rope in

accordance with RR-W-410, type I, class 4, except that the rope shall be galvanized. A cast or forged

steel ring conforming to the dimensions shown on figure 8 shall be attached to the other end of the wire

rope. Thimbles shall be used in securing the wire rope to the grapnel and in securing the ring to the wire

rope. Thimbles shall be in accordance with type III of FF-T-276. The wire rope connections to the

grapnel and to the ring shall be made with a minimum of two 1/2 inch (.5in/12.7mm) wire rope clips to

each connection.

3.4 Tolerances.

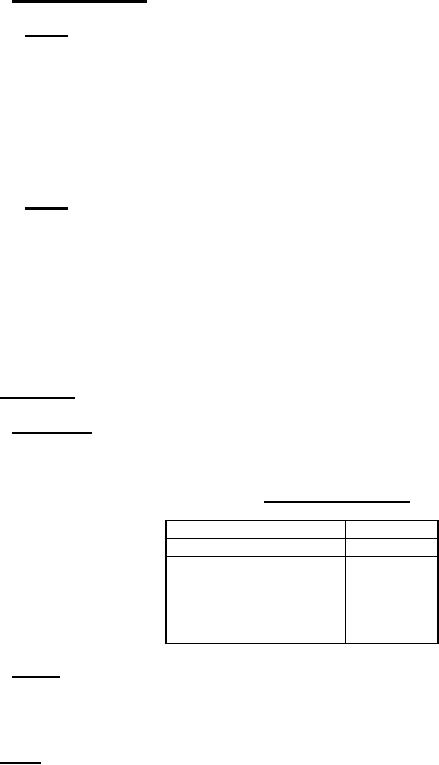

3.4.1 Dimensions. The tolerances and dimensions specified in table V will be permitted, provided that

any combination of tolerances and dimensions used shall not result in a grapnel that exceeds the weight.

tolerances (see 3.4.2).

TABLE V. Dimension tolerances.

Dimensions

Tolerance

Inches (mm)

Inch (mm)

Up to 1

(up to 25)

.06 (1.6)

1-.13 to 2 (29 to 51)

.13 (3.2)

2-.13 to 6 (54 to 152)

.25 (6.4)

6-.13 to 12 (156 to 305)

.38 (9.7)

Over 12

( over 305)

.50 (.13)

3.4.2 Weight. For type I, all sizes, and type II, sizes 1 and 2 grapnels, a tolerance in weight of not

more than 4 percent nor less than 2 percent of the nominal weight will be permitted. For type II, sizes 3,

4, and 5, type III, and type IV grapnels, a tolerance in weight of not more than 10 percent nor less than 5

percent of the nominal weight will be permitted.

evenly coated with galvanized hot dip process as specified in ASTM A153/A153M. All chains, rings, clips,

thimbles and hooks shall be galvanized as specified in ASTM B633 or ASTM A153/A153M. Pear links

and other attaching links and rings may be cold galvanized per MIL-P-21035 after welding. The coating

shall be adherent, uniform, smooth, and free from uncoated spots or injurious lumps, pits, blisters, acid

and black spots, dross and flux.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business